Hello everyone!!!

I had a thought of developing an Android application for a

long time. I created an application successfully and became little familiar now

on how to create an android app using processing software.

Professional android apps are developed using eclipse, but

it is very tedious for me to learn because of lack of knowledge in Java. My

friend gave me an idea that we can create android apps using processing under

android mode easily which uses basic C syntax. I tried it and became successful

within a short period.

Refer the link below to learn android processing. I recommend it for

developing simple to medium complexity android apps.

All you have to do is to download Processing software from

the following link.

Then open processing, initially on the top right corner Java

mode will be seen. We need to change to android mode to create android apps. I

will show you the shortest way to create unsigned android app for the program

written. Signed app can be created by following the steps available in the

internet to distribute the developed app in Google Play (which I haven’t tried).

Click the Java mode on top right corner, from the drop down

select add mode. Then install android mode from the newly opened window.

Now the top right corner will change to android mode. Write

the code and select sketch à

run in emulator. To run in emulator you have to install latest JDK, the steps

to do it is given in processing website.

After selecting run in emulator, you can see some texts

running on the console. After the “debug” text appear on the console, move few

lines back to see the link which ends with .apk extension.

Copy the link and paste it in Run from start menu. Then a

window opens where the apk file for the program exist. We can copy and install

in android phone to run the app.

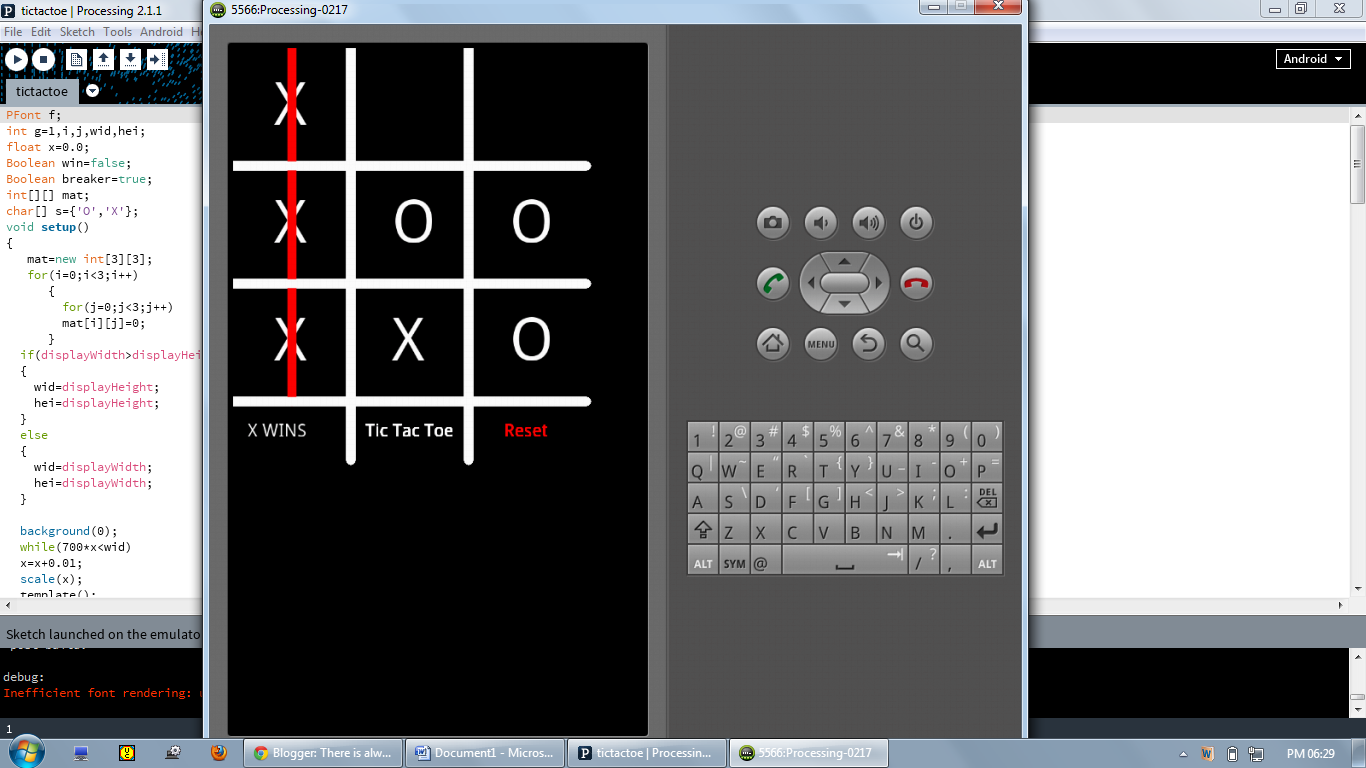

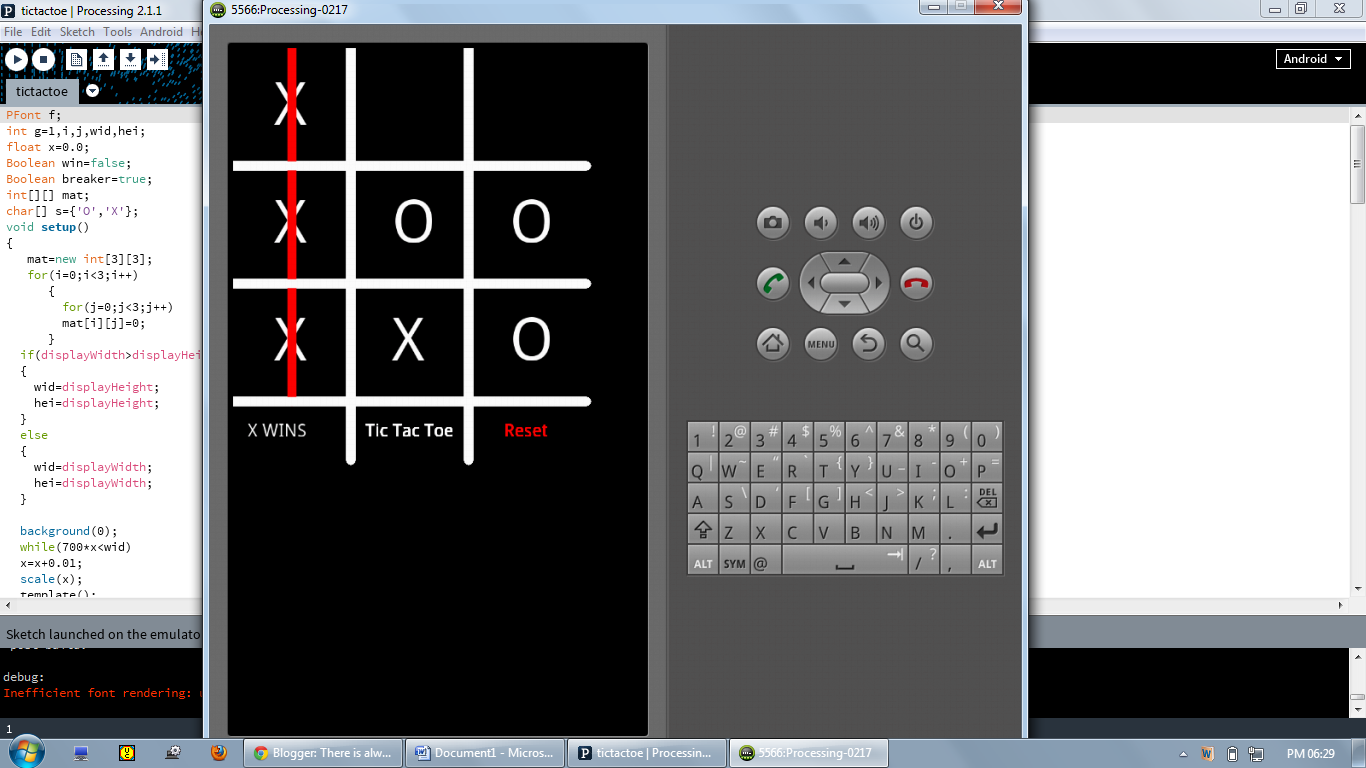

The code running in emulator

Code for the Tic Tac Toe application is given below.

PFont f;

int g=1,i,j,wid,hei;

float x=0.0;

Boolean win=false;

Boolean breaker=true;

int[][] mat;

char[] s={'O','X'};

void setup()

{

mat=new int[3][3];

for(i=0;i<3;i++)

{

for(j=0;j<3;j++)

mat[i][j]=0;

}

if(displayWidth>displayHeight) // For scaling different screen sizes

{

wid=displayHeight;

hei=displayHeight;

}

else

{

wid=displayWidth;

hei=displayWidth;

}

background(0);

while(700*x<wid)

x=x+0.01;

scale(x);

template();

}

void draw()

{

scale(x);

if(mousePressed && breaker==true)

{

f=createFont("Georgia",100);

textFont(f);

fill(255);

if(mouseX<2*wid/7&&mouseY<2*hei/7&&win==false)

{

text(s[g],70,130); //1st box

mat[0][0]=g+2;

}

else if(mouseX<4*wid/7&&mouseY<2*hei/7&&win==false)

{

text(s[g],270,130);//2nd box

mat[0][1]=g+2;

}

else if(mouseX<6*wid/7&&mouseY<2*hei/7&&win==false)

{

text(s[g],470,130);//3rd box

mat[0][2]=g+2;

}

else if(mouseX<2*wid/7&&mouseY<4*hei/7&&win==false)

{

text(s[g],70,330);//4th box

mat[1][0]=g+2;

}

else if(mouseX<4*wid/7&&mouseY<4*hei/7&&win==false)

{

text(s[g],270,330);//5th box

mat[1][1]=g+2;

}

else if(mouseX<6*wid/7&&mouseY<4*hei/7&&win==false)

{

text(s[g],470,330);//6th box

mat[1][2]=g+2;

}

else if(mouseX<2*wid/7&&mouseY<6*hei/7&&win==false)

{

text(s[g],70,530);//7th box

mat[2][0]=g+2;

}

else if(mouseX<4*wid/7&&mouseY<6*hei/7&&win==false)

{

text(s[g],270,530);//8th box

mat[2][1]=g+2;

}

else if(mouseX<6*wid/7&&mouseY<6*hei/7&&win==false)

{

text(s[g],470,530);//9th box

mat[2][2]=g+2;

}

else if(mouseX>4*wid/7&&mouseY>6*hei/7)//reset

{

for(i=0;i<3;i++)

{

for(j=0;j<3;j++)

mat[i][j]=0;

}

win=false;

background(0);

}

for(i=0;i<3;i++)

{

stroke(255,0,0);

if((mat[0][0]==g+2&&mat[1][1]==g+2&&mat[2][2]==g+2))

{

line(0,0,600,600);

win=true;

}

else if((mat[0][2]==g+2&&mat[1][1]==g+2&&mat[2][0]==g+2))

{

line(0,600,600,0);

win=true;

}

else if((mat[0][i]==g+2&&mat[1][i]==g+2&&mat[2][i]==g+2))

{

line(100+(i*200),0,100+(i*200),600);

win=true;

}

else if((mat[i][0]==g+2&&mat[i][1]==g+2&&mat[i][2]==g+2))

{

line(0,100+(i*200),600,100+(i*200));

win=true;

}

}

if(win!=true)

{

g=g+1;

if(g==2)

g=0;

}

template();

breaker=false;

}

if(breaker==false && mousePressed==false)

breaker=true;

}

void template()

{

stroke(255);

strokeWeight(15);

fill(255);

line(200,0,200,700);

line(400,0,400,700);

line(0,200,600,200);

line(0,400,600,400);

line(0,600,600,600);

f=createFont("Georgia",30);

textFont(f);

text("Tic Tac Toe",225,660);

fill(255,0,0);

text("Reset",460,660);

fill(0);

noStroke();

rect(20,625,125,50);

f=createFont("Georgia",30);

textFont(f);

fill(255);

if(win==true)

{

text(s[g],25,660);

text("WINS",50,660);

}

else

{

text(s[g],25,660);

text("'s Turn",50,660);

}

}